water vapor permeability test procedure sourcing|water vapor permeability : convenience store Water Vapor Transmission ASTM E96. The test evaluates the water vapor transfer through semi-permeable and permeable samples. The data can be used by manufacturers and .

ArenaMate® designs and manufactures specific maintenance equipment for equestrian riding surfaces. We have over 35 years of expertise in engineering. Everything is made in house in the UK. As equine enthusiasts ourselves, we understand the way of life and strive to make our customers feel at home with us.

{plog:ftitle_list}

WEBEstamos certos do seu TRIUNFo. Mesmo nos momentos mais desafiantes, desfrute da vida sem preocupações.

Detailed video explanation of ASTM E96-22 standard desiccant and water test methods for water vapor transmission rate of materials.Determine the Water Vapor Transmission Rate (WVTR) of any material; not just insulation and vapor retarders. From WVTR, Water Vapor Permeance (WVP) is calculated for the test . The most widely used method to measure the water vapor permeability is ASTM Standard Test Method E96 (https://www.astm.org/Standards/E96.htm), also well-known as the cup .

Parameters relating water vapor permeability is calculated after testing the water vapor transmission rate of the specimen under specified temperature and relative humidity. .The modified procedure for water vapor permeability (WVP) is a modification to the established ASTM E96 method for measuring the WVP of films. The E96 method works by putting water in .Water Vapor Transmission ASTM E96. The test evaluates the water vapor transfer through semi-permeable and permeable samples. The data can be used by manufacturers and .“water vapor permeability—the time rate of water vapor transmission through unit area of flat material of unit thickness induced by unit vapor pressure difference between two specific .

Water Vapor Transmission is calculated using the formula: WVT = G / t A= (G / t) / A (G=weight gain; t=time tested; A=area of the test area or dish opening) Two of the methods to test the .

water vapor permeability measurement

This test measures water vapor transfer via semi-permeable and porous samples. The ASTM E96 test measures the rate at which water vapor passes through a material over time, and the .The test evaluates the water vapor transfer through semi-permeable and permeable samples. The data can be used by manufacturers and designers and is often important in packaging applications. Test Procedure: A cup is filled with distilled water leaving a small gap (0.75" to 0.25") of air space between the specimen and the water. the author analyzes influencing factors of water vapor permeability testing methods for plastic films (package). Meanwhile, some suggestions for improvement are put forward. Key Words: water vapor permeability, water vapor transmission rate, cup method, sensor method, desiccant method and water method 1.Overview:FIELD MANUAL 110 Table 17-1.—A glossary of abbreviations and definitions used in permeability calculations K = Coefficient of permeability in feet (meters) per year under a unit gradient. Q = Steady flow into the well in ft3/sec [m3/sec]. H = The effective head of water in the well in feet (m). For packer tests, determining the effective head is defined

water vapor transmission rate Ñthe steady water vapor ßow in unit time through unit area of a body, normal to speciÞc parallel surfaces, under speciÞc conditions of temperature and humidity at each surface.Ó 4. Summary of Test Methods 4.1 In the Desiccant Method the test specimen is sealed to

water vapor permeability

Definition of WVP – Water Vapor Permeability. The vapor quality passing through the unit area sample vertically in the prescribed time at the speed of g/m² Cup experiments are the most widely used method to measure the water vapor permeability of porous building materials. For this test, cup assembly is designed to create a vapor pressure gradient across a sample and, thus, to allow vapor diffusion through it. Water vapor permeability is assessed by weighing cup assembly over time.

While water vapor generally cannot harm humans, since it is just water in a different state of matter, it can be troublesome for many materials used for different purposes. Determining the water vapor transmission rate (WVTR) of a multitude of materials through ASTM E96-22 testing procedures is essential for moisture control. Knowing this can .

Modified upright cup method for testing water vapor permeability in porous membranes . it is important to be sure that these membranes are analyzed and tested to the same test method and procedure [19]. This property . The uncertainty of the thickness due to the calibration of the caliper constitutes another source of uncertainty considered .ASTM E96 Full Name. ASTM E96 – Standard Test Methods for Water Vapor Transmission of Materials. Scope. ASTM E96 outlines standardized test methods to determine the water vapor transmission rate of materials. This property, crucial in construction and packaging industries, quantifies the amount of moisture that permeates a material over a specific area and time.

permeability of a body that performs like a material may be used. Permeability is the arithmetic product of permeance and thickness. water vapor permeance Ñthe time rate of water vapor transmission through unit area of ßat material or construction induced by unit vapor pressure difference between two speciÞcLearn why water vapor permeation testing matters. Close Search. Displaying - of results for . All Filter your results Products Applications Knowledgebase Video Standards . Permeability Testing. Permeation Testing. . with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. . propose a new test procedure to measure the water vapor diffusion coefficient, considering the total gas pressure. In this paper, we are interested in analyzing 45

us drop entry testing

B# Water Upright 73.4℉ (23 ℃) 50% BW# Water Inverted 73.4℉ (23 ℃) 50% C Solid Desiccant Upright 90 ℉ (32.2 ℃) 50% D Water Upright 90 ℉ (32.2 ℃) 50% E Solid Desiccant Upright 100℉ (37.8 ℃) 90% (#)More common procedures adopted in the market WATER VAPOR PERMEABILITY (WVP), BS 7209 PROCEDURE METHOD CUP ORIENTATION . A correlation between water vapor permeability and density is established. The analysis of liquid uptake by X-ray radiography shows that preferential uptake occurs in the latewood layer.

Two general types of permeability test methods are routinely performed in the laboratory: (1) the constant head test method, and (2) the falling head test method. The constant head test method is used for cohesionless and more . Load the test sample onto the test cup. The water vapor permeability tester places the positive cup in the test apparatus. After equilibrating, weigh the object to obtain its initial weight. Then, testers test and . Standard test methods for water vapor transmission of materials. E96-95. In Annual Book of ASTM Standards American Society for Testing and Materials, Philadelphia. Google Scholar. Bader and Göritz, 1994. . modified procedure for water vapor permeability and explanation of thickness effects. Journal of Food Science, 58 (4) (1993), pp. 899-903.

Permeability of Common Building Material to Water Vapor WHAT IS A PERM RATING? If a material has a perm rating of 1.0, 1 grain of water vapor will pass through 1 square foot of the material, provided that the vapor pressure difference between the cold side and the warm side of the material is equal to 1 inch of mercury (1 inch Hg). Various Water Vapor Permeability Testing Methods and Procedures Water Vapor Transmission ASTM E96, JIS L 1099,ISO 15496, Water Vapor Permeability (WVP), BS 7209 and differences between BS 7209 and other cup methods as well as differences between cup methods and sweating hot plate methods are summarized within the latest Safeguards .Water vapor permeability is one of the main performance indexes of package materials. As people are attaching more importance to the damp proofing and waterproofing of products, package materials with smaller water vapor permeability becomes the f.3us of package material development and application and is receiving more and more concentrations in recent years.“water vapor permeability—the time rate of water vapor transmission through unit area of flat material of unit thickness induced by unit vapor pressure difference between two specific surfaces, under specified temperature and humidity conditions. 3.1.1 Discussion—Permeability is a property of a material,

us drop international covid testing

ASTM D 1653 is a standard test method used to determine the permeability of organic coatings to water vapor and gases. The test involves immersing coated test panels in water or other liquids, and measuring the rate of water vapor or gas transmission through the coating.The water vapor transport (WVT) rate for the treated fabrics was evaluated by using a circular fabric sample with a total exposed area of 1.65 cm 2 . 46, 60, 61 This method follows the guidance .Moisture vapor transmission rate (MVTR), also water vapor transmission rate (WVTR), is a measure of the passage of water vapor through a substance.It is a measure of the permeability for vapor barriers.. There are many industries where moisture control is critical. Moisture sensitive foods and pharmaceuticals are put in packaging with controlled MVTR to achieve the required . Moreover, Paraloid B44 and B72 are used as references when introducing new materials in the conservation practice.6,7,8,9,10,11,12,13,14,15,16,17,18 The available water vapor permeability data of these materials, such as water vapor transmission rate (WVTR) or moisture vapor transmission rate (MVTR), permeability coefficient (P), solubility or .

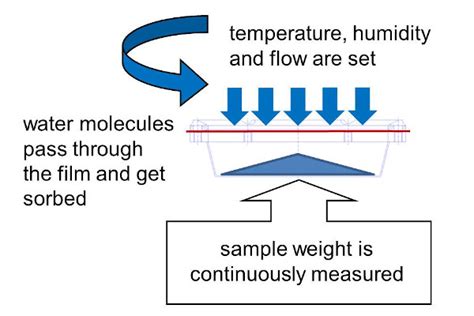

This provides a basis to water vapor permeability testing under special conditions. 2.2 Reference Standard: ASTM E 96 . ASTM E96 is the gravimetric standard with the longest history. It is also the longest-standing standard method for water vapor permeability testing. The first edition was issued in 1953 and has been revised for many times .gravimetric method, water vapor permeability testing, wvtr, transmission rate . which is the main source of testing errors. On one hand, cup movement destroys the transmitting equilibrium of water vapor to specimen because of environment difference (generally, weighing is carried out in the lab and the environment is 23/50; however, testing .

Resultado da Click the Browse button to select the video you want to compress for WhatsApp. Step 2. Set the specs - you can choose the quality level, video resolution, and whether .

water vapor permeability test procedure sourcing|water vapor permeability